SBS

The Power to Stop YouScandinavian Brake Systems A/S is the world’s leading manufacturer of motorcycle brake pads for street, off road and racing.For more than 30 years SBS’S aim has always been to offer the most complete range of motorcycle brake pads in a variety of friction materials developed to suit specific purposes like street, off-road and racing – always based on our philosophy: “The highest performance of Brake System Technology can only be achieved by selecting the best friction materials”. Off Road PadsSI – Sinter Brake Pads Mud or sand, heavy rain and grinding conditions – SBS SI Sinter Off-Road offers pad life durability for extreme conditions.RSI – Off-Road Racing Brake Pads If you are racing for the podium in motocross, SBS RSI Sinter Off-Road Racing should be your choice. RSI provides a powerful, predictable and fade-free brake performance, even under the extreme racetrack conditions.

|

|

| SBS Road Riding & Touring padsStreet excel Sinter HS – Front Brake Pads The perfect combination of fade free brake performance, brake feel and thermal stability, especially developed for sport riding and high loads from heavy motorcycles. The HS lining is rotor friendly, the performance is stable under dry as well as wet conditions and no thermal bedding-in is required. Recommended for new generation high performance, sports, touring and custom motorcycles which are originally equipped with sinter metal brake pads.Street excel LS sinter – Rear Brake Pads Sinter metal brake lining LS for the rear brake with high thermal stability which in combination with HS for the front brake provides the necessary and expected brake performance. To avoid excessive braking of the rear wheel, the friction level of the LS lining is adjusted to match the friction characteristics of the HS lining, according to the concept of the originally equipped sinter metal brake pads.Street Excel HF Ceramic – Front/Rear Brake Pads Stable brake performance for front and rear brake. High level of comfort and long-lasting brake pads and rotor friendliness under various conditions such as wet roads, changing temperatures and different brake pressures. Recommended for earlier Sport, Touring and Custom models as well as daily transport and touring on small motorcycles which are mainly not originally equipped with sinter metal brake pads.  |

|

| SBS Racing Brake PadsDC – Dual Carbon Brake Pads Used by the world’s top teams and riders since 2001 introduction to win 7 World Championship titles and numerous of National Championships. DC is the “The choice of Champions” for Superstock, Supersport and Superbike classes. Find DC bedding-in instruction and technical information at www.sbs.dkDS – Dual Sinter Brake Pads Introduced 2007 for World Superbike, Supersport & Endurance, winning the 2 sprint Championships and doing the complete 24 Hour race distance of Lemans & Bol dór in it´s 1st season. DS proved already to be the new standard in brake pad technology for World Championship Racing & Endurance. |

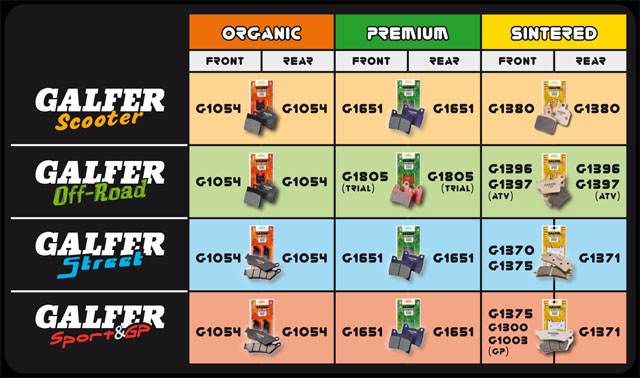

Galfer

Rotors for Street / Sport / Racing

|

Invented by Galfer in the early 90′s to solve the problem of water and mud on brake rotor surfaces of trial competition motorcycles. As we developed the design we discovered an added benefit: the brake system was running cooler. This was worth exploring. When we combined our new design with the premium materials we had already developed for our round rotors, the resulting breakthrough began the new generation of brake rotor technology.

|

|

Standard Wave® Rotor |

|